Simultaneous Operations (SIMOPS) for Multi Wellpad DevelopmentTEST

What is SIMOPs and How is it Different from Normal Operations?What is SIMOPs and How is it Different from Normal Operations?

Concurrent Operations (CONOPS) - Concurrent Operations are two or more potentially higher risk, non- routine activities carried out in close proximity in space and time, but under a single organization’s management system (e.g PtW).

Simultaneous Operations (SIMOPs) occur when two or more potentially higher risk, non- routine activities are carried out by multiple contractors and/or a large multi-disciplinary workforce in close proximity in space and time using their own work procedures and safety management systems.

CONCURRENT OPERATIONS (CONOPS)

For example, hot works carried out by maintenance contractor on a producing facility

SIMULTANEOUS OPERATIONS (SIMOPS)

.png)

HOW ARE SIMOPS RISKS MANAGED

SIMOPS Risks are managed:-

RISK ASSESSMENT(S) TO AID SIMOPS

QRA may be performed to work out a SIMOPS control area in case the consequence distances may be very large . E.g. presence of large fractions of H2S.

Criteria of IRPA, LSIR and threshold concentrations of H2S at specified frequencies per year can be utilised.

Recommendations such as those regarding siting, layout, F&G provisions, shielding etc may also be identified.

.png)

SOME TYPICAL HAZID OUTCOMES – SIMOPS RESTRICTIONS / CONSTRAINTS

Any well control event (e.g. kick) or well integrity event (producing well) will lead to an immediate and a complete suspension of any SIMOPS activities.

Producing wells or pressurised pipelines/ flowlines/ manifolds within the drop zone are provided with sufficient impact protection for the duration of the lifting activity.

No offloading of equipment or lifting activities for drilling permitted in high winds (more than 20 mph).

F&G detection systems must be available to Drilling or Operations on Multi-Well Locations at all times i.e. F&G Systems on adjacent wells must be operational or a temporary system installed.

Drilling, workover and CWI not permitted during well integrity emergencies requiring maintenance of an adjacent well.

No operations permitted within the mast radius during mast up/ down. All wells within mast radius shut in and provided with drops protection; production facilities within mast radius isolated and de-pressurised.

Restricted vehicle movement on well pad during raising and lowering of mast.

All CWI operations requiring breaking Lubricators, etc. must be conducted with Breaching

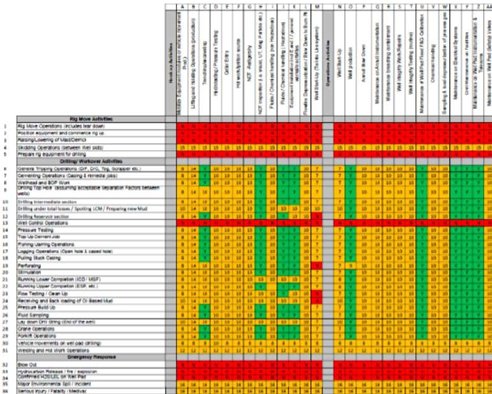

INFORMATION FROM RISK ASSESSMENTS FEEDS INTO THE SIMOPS MATRIX OF PERMITTED OPERATIONS (MOPO)

.png)