Safety Management Systems

PGL Consultants are highly experienced in architecting and developing SMS for organisations trying to get started. We can also help you in evolving or improving the existing SMS for your organisation.

We have strong capabilities to guide an organisation from drafting of safety policy up to auditing and review. Our SMS capabilities include all the intermediate requirements of processes, procedures, safety assessments, operations support and ALARP demonstration.

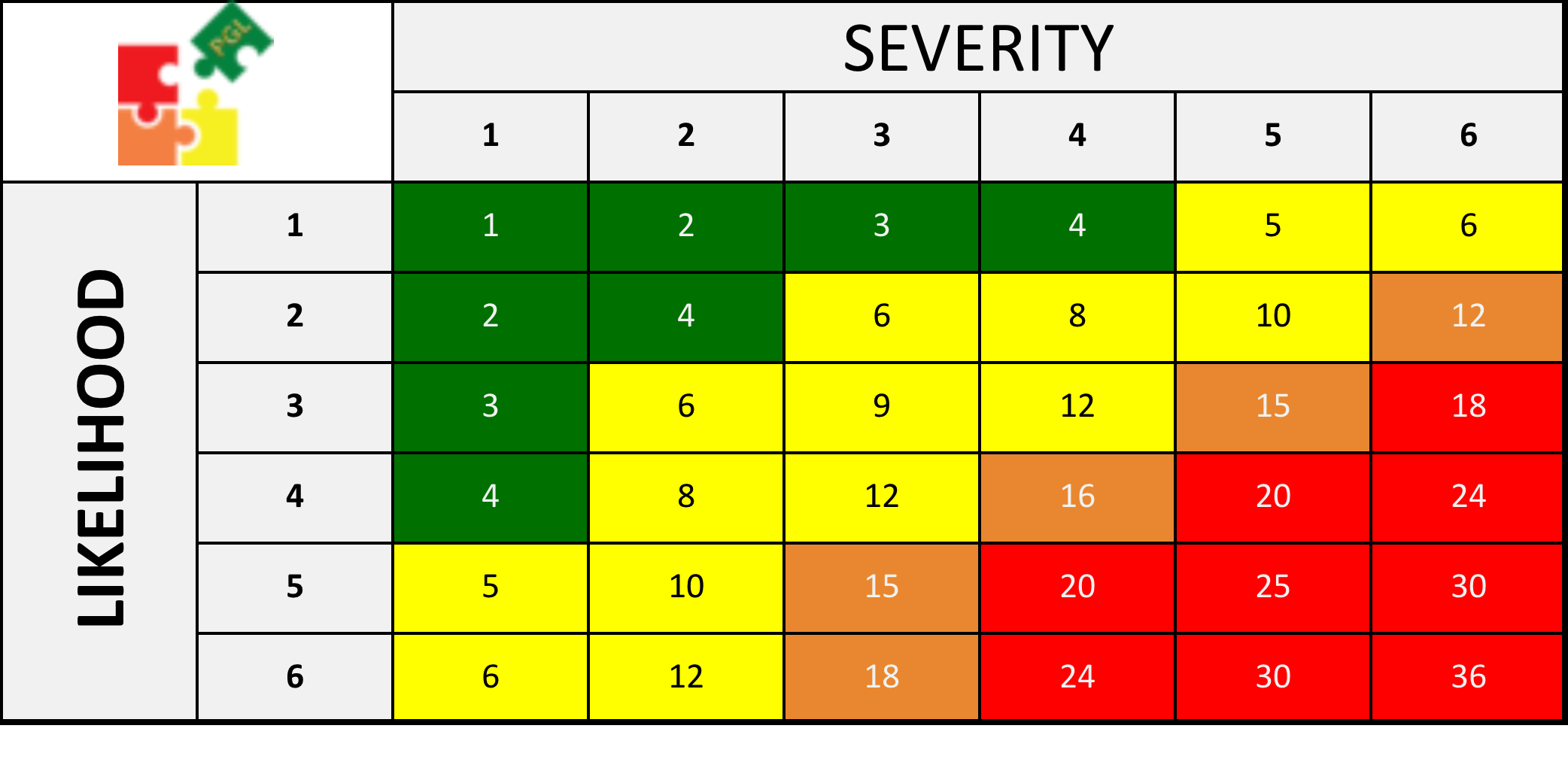

Process Safety and HSE Assessments & Reviews

PGL Team has extensive experience in Process Safety and HSE studies for the Oil & Gas, Hazardous Chemicals, Wind Farms, Hydrogen and Carbon di Oxide. A typical List of safety reviews which our consultants can deliver for your next project is provided below (not an exhaustive account)

Risk Review Facilitations : HAZID, ISD, HAZOP, C-HAZOP, SAFOP, ALARP, SCE Identification using LOPA and /or Bow-Ties

Consequence Modelling and Major hazard quantified risk assessment

Functional Safety including SIL Assessments and Verifications and SRS development

Technical Risk Assessments

Inherently Safer Design (ISD)

SIMOPS and COMOPS

Emergency Planning and crisis management

ALARP and Cost

Benefit Analysis Demonstration

Safety is obviously number one priority in our philosophy of carrying out assessments. But, practicality in terms of operations and closing of recommendations always remains a considerations with our consultants. Therefore, your organisation can always be assured of a sensible study with us.

We are very much interested to hear from you if you are looking for help on a novel concept or an out of the box solution. Some examples of such studies we have carried out in the past include assessments of : microwave radiation from a radar, Cost Benefit of PFP on windfarm sub-station, hydrogen infrastructure on the UK roads, hazards of super critical CO2, Globally Harmonised System of Chemicals and many more.

Operations support

PGL has extensive experience in helping out Operations Teams in debottlenecking process safety issues or retrofitting state-of the-art process safety / loss prevention. Some of the typical projects our consultants have recently delivered include Valve Criticality Analysis, Control Room Ergonomics, using LOPA or Bow-Tie methodologies to identify SCEs and maintenance priorities, SIMOPs Management and revalidation of existing safety reviews. Our philosophy is to provide a deliverable ‘over-and-above’ the run-of-the-mill risk assessment, the one which can provide useful insights to enable management make confident and informed choices.

We can also help in defining and revising the Safe Operating Envelopes and operating procedures, following the changes in process parameters over time or general ageing of an assets.

we can also cater to an organisation’s competency management and training needs through our regular or customised in-house training

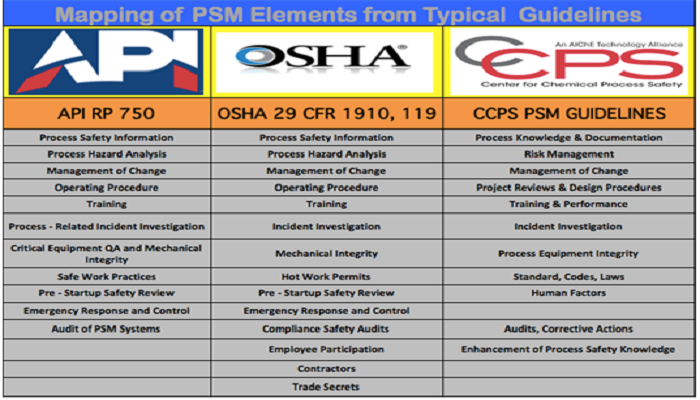

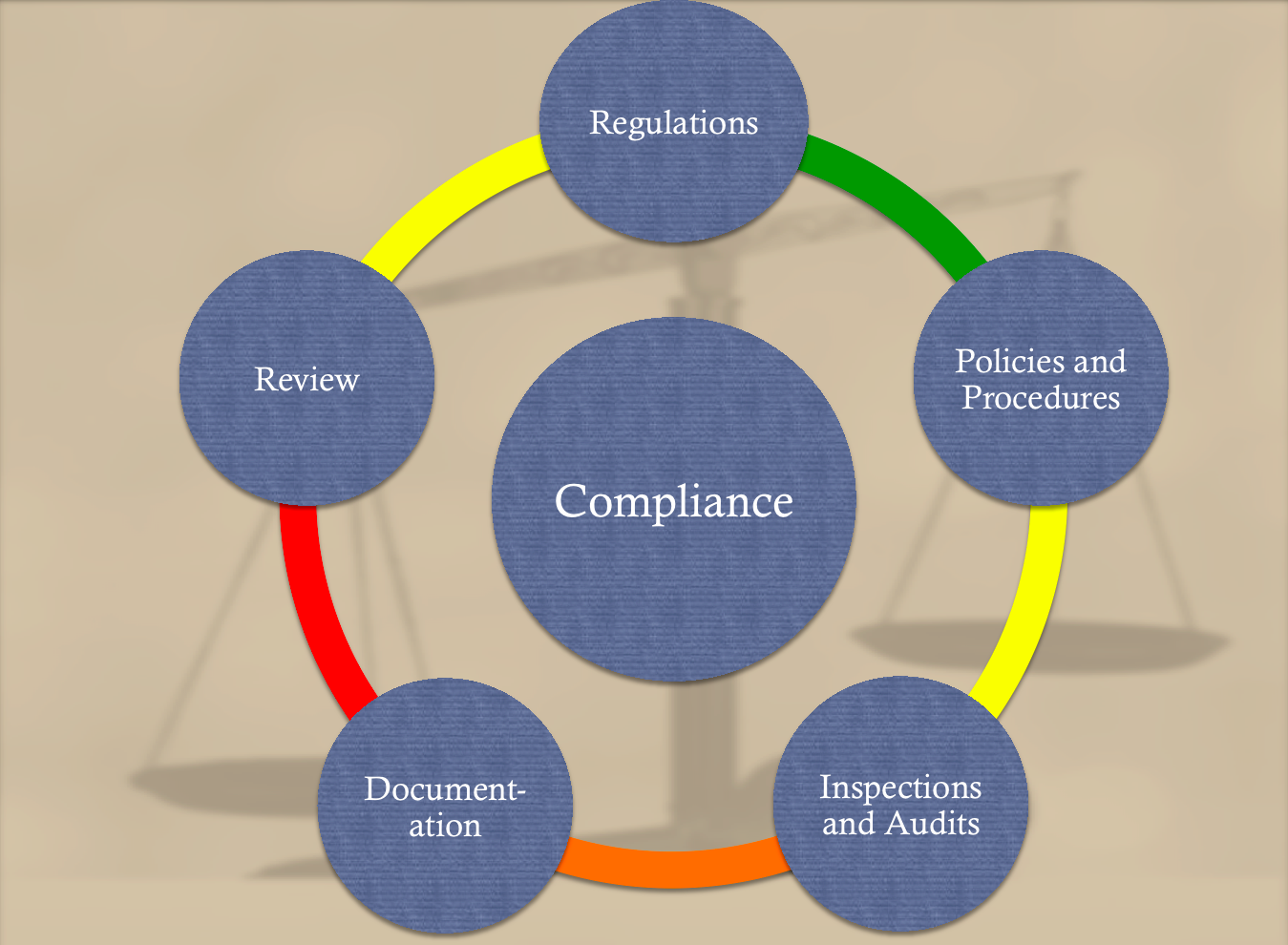

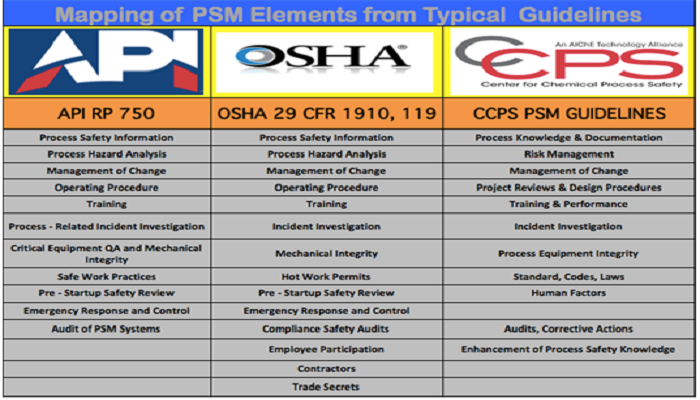

Assurance and Compliance

PGL has a team of consultants experienced in global HSE and Process safety legislations. Be it a report to provide evidence of UK’s PFEER, COMAH or Safety Case Regulation or providing such support for a newly formed regulation in any part of the world, our experts can make the journey easy and the destination pleasant for you.

We also have a great team of certified auditors for various services and international standards. We can provide you immaculate support for preparations and recommendation close-outs for Safety auditing, Operational Procedures Compliance Audits, Independent review of Safety Cases, COMAH Reports and Safety Manuals etc. We can help you prepare for your next insurance visit, including providing professional advice on how to safely but realistically and cost-effectively close the insurance recommendations.

Procedures and Template Development

If your organisation is overwhelmed with the sheer number of procedures and documentation then PGL shall be your obvious go-to place. We have extensive experience in streamlining the procedures and standards in organisations. This exercise directly reduces the costs in capital projects and also helps avoid surprises during the EPC stage.

We also have extensive experience in development of Process Safety and Operational Procedure and Guidelines, where they do not exist. Some of our recent works include developing the following procedures:

Design Safety Reviews and Assessments

HAZOP, C-HAZOP and SAFOP

Process Hazard Analyses

SIL Reviews

ESD and EDP Design

Fire and Explosion Risk Assessments

Active and Passive Fire Protection Design

Simultaneous Operations (SIMOPs)

Operations and Maintenance

Process Safety Overrides,

Mechanical

Isolation and Start-up Safety

Plant Safety Override

Hot Tapping

Bolting and Flange Opening

Looking for something novel or specific?

We are very much interested to hear from you if you are looking for help on a novel concept or an out of the box solution. Some examples of such studies we have carried out in the past include assessments of : microwave radiation from a radar, Cost Benefit of PFP on windfarm sub-station, hydrogen infrastructure on the UK roads, hazards of super critical CO2, Globally Harmonised System of Chemicals and many more.test